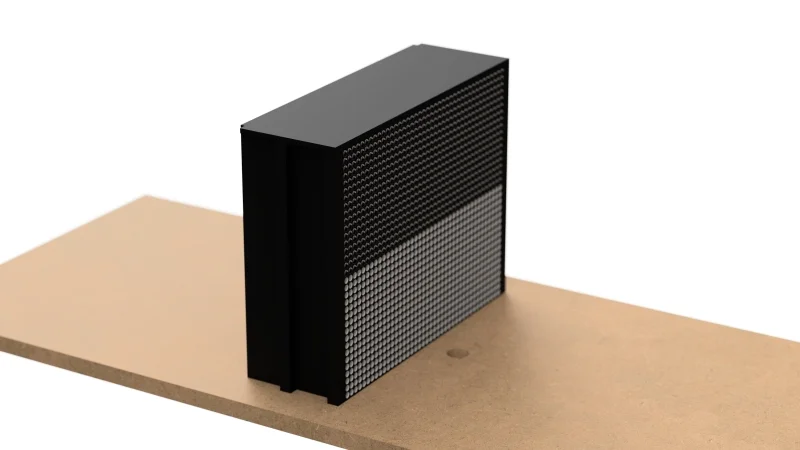

Wind Tunnel

A compact wind tunnel for airflow experiments and aerodynamic testing.

To view the current progress, click the link below:

View Progress →This project was made possible as a result of the generous support provided by local firms. I would like to thank:

Waveney Precision

Supporting the project by supplying the acrylic for the entire project.

Check them out! →

This desktop wind tunnel was designed for hands-on aerodynamic testing and educational demonstrations. It features a compact footprint, variable-speed fan, and a clear test section for visualizing airflow over models.

The primary goal of the project was initially to create a wind tunnel capable of data collection as well as visual aerodynamics, however, this goal has shifted towards an entirely visual focus following further analysis of the design.

A high speed (~100mph) design is coming soon. To stay up to date, check out V2.

Take me there →

- Frame: 3D printed

- Materials: PLA, 3mm acrylic, 18mm MDF

- Fans: 9x Arctic P12 PC fan

- Test section: 500mm long x 350mm wide (300mm useable) and 250mm tall

- Features: Smoke injection port, detailed visual aerodynamic analysis, large test section

This project came to mind after an F24+ race at the Lotus Hethel Test Track. Seeing other cars with advanced aerodynamic shapes and impressive designs inspired me to start a new project. This new project came from a mix of the forced induction seen on some cars, used to cool their motors, and the aerodynamics they used. Aero + forced induction = wind tunnel.

Although on a different scale, this wind tunnel is not my first design. Back in primary school, as part of the Jaguar Primary School Challenge, I build a small wind tunnel to test our car (pictured below). From this design, I learnt about attempting to get clean flow and the method I used was plastic straws before the test section to straighten air flow before flowing over the model. Unfortunately, no images exist of the tunnel working, however, the smoke used to visualise worked excellently.

The first design had its flaws:

- Messy smoke - difficult to make detailed analysis

- Not completely laminar flow

- Smoke from unsuitable source (leading to melting of air straightener straws as seen above)

Now, with access to CAD software and advanced manufacturing using 3D printing, I can take what I have learnt and develop a wind tunnel with more advanced features.

Coming soon...