19th October 2025

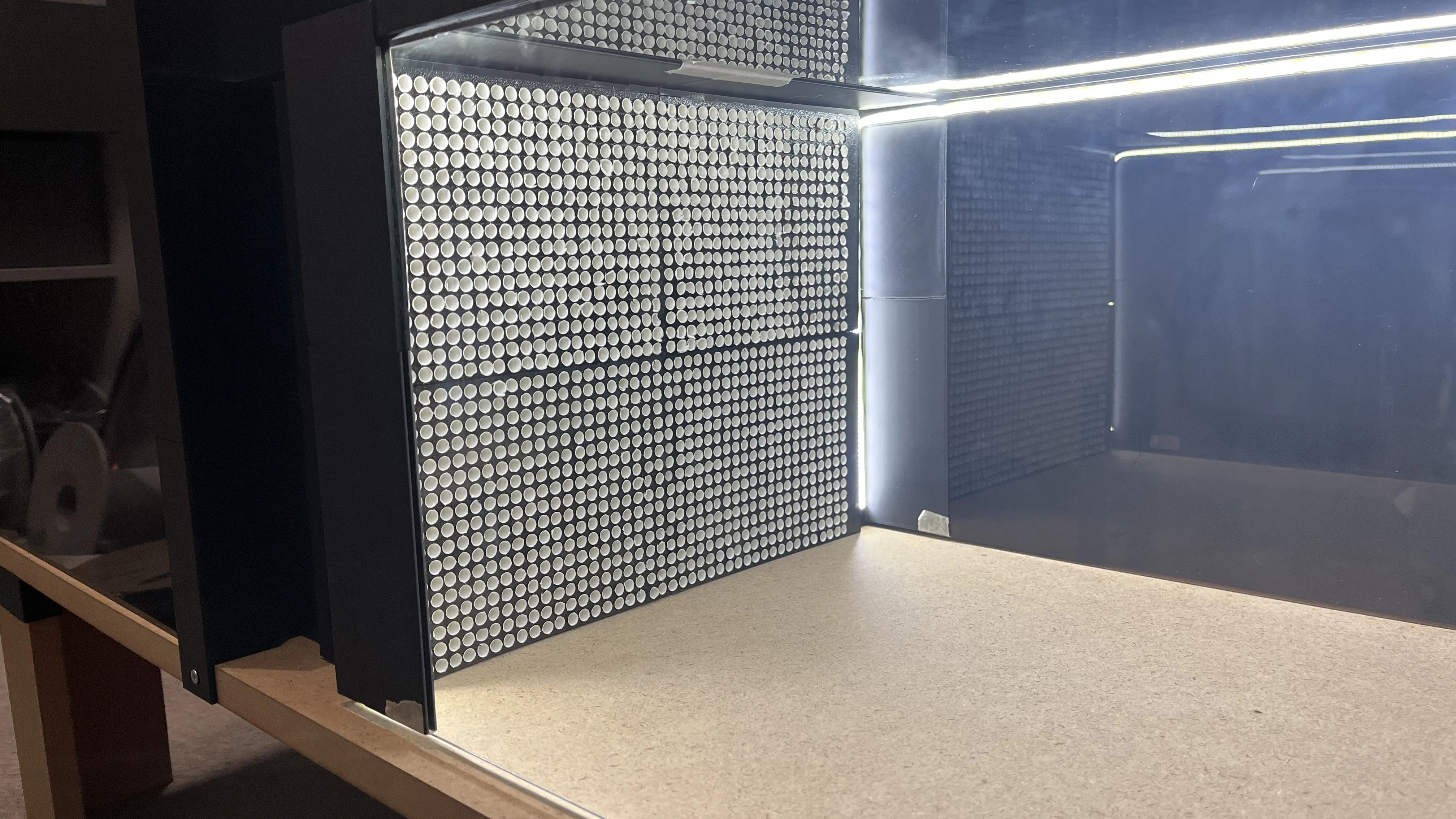

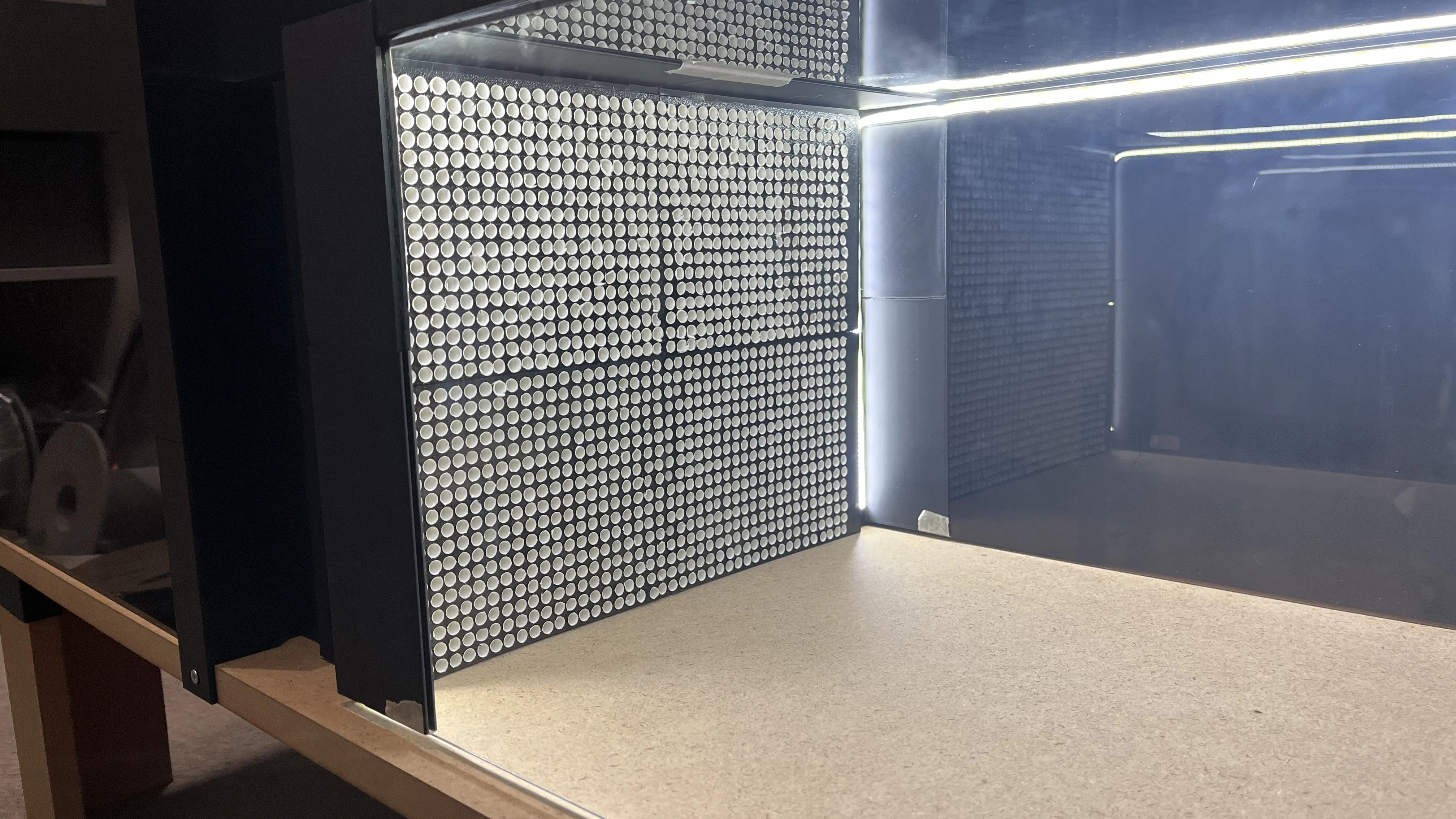

Now that the airflow straightner is complete, it can be added after the plenum to allow the test section and plenum to be joined.

The development of a deep understanding of aerodynamic concepts

This project was made possible as a result of the generous support provided by local firms. I would like to thank:

Supporting the project by supplying the acrylic for the entire project.

Check them out! →19th October 2025

Now that the airflow straightner is complete, it can be added after the plenum to allow the test section and plenum to be joined.

19th October 2025

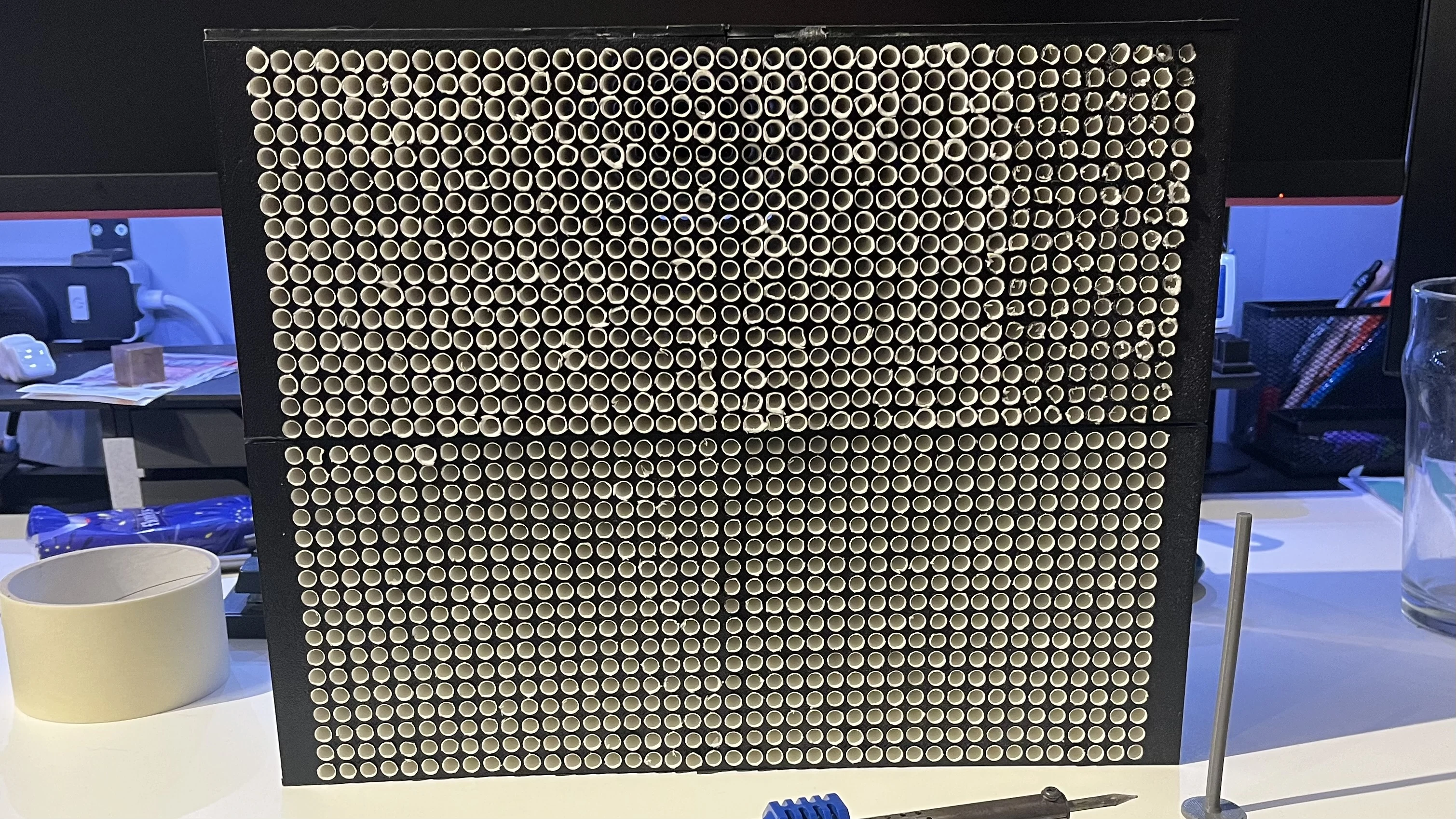

The airflow straightener is made of over 1300 paper straws, which each needed to be added to a 3D printed frame. With all of the straws inserted and the frame assembled, the straightener is ready to be added to the wind tunnel.

12th October 2025

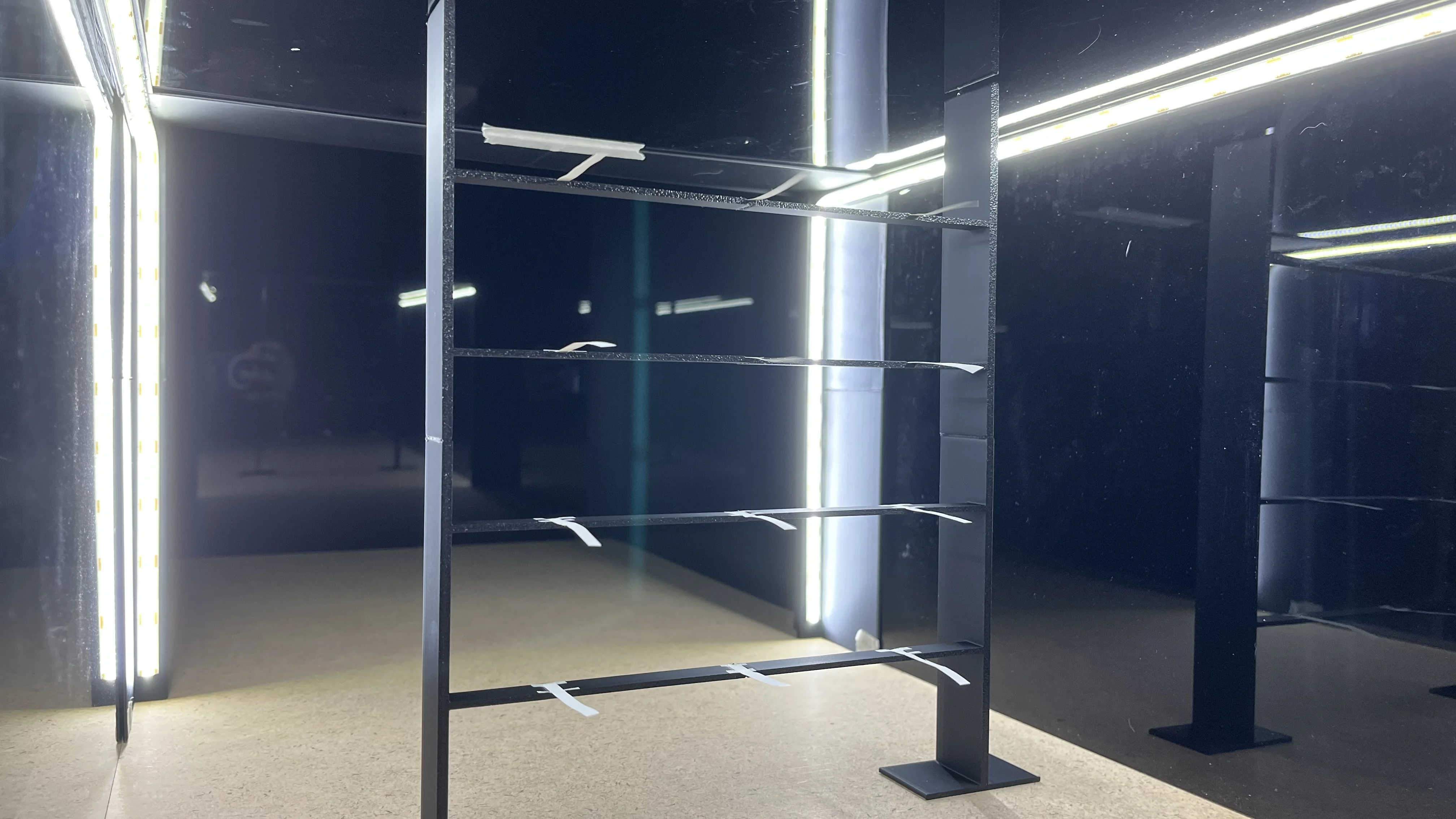

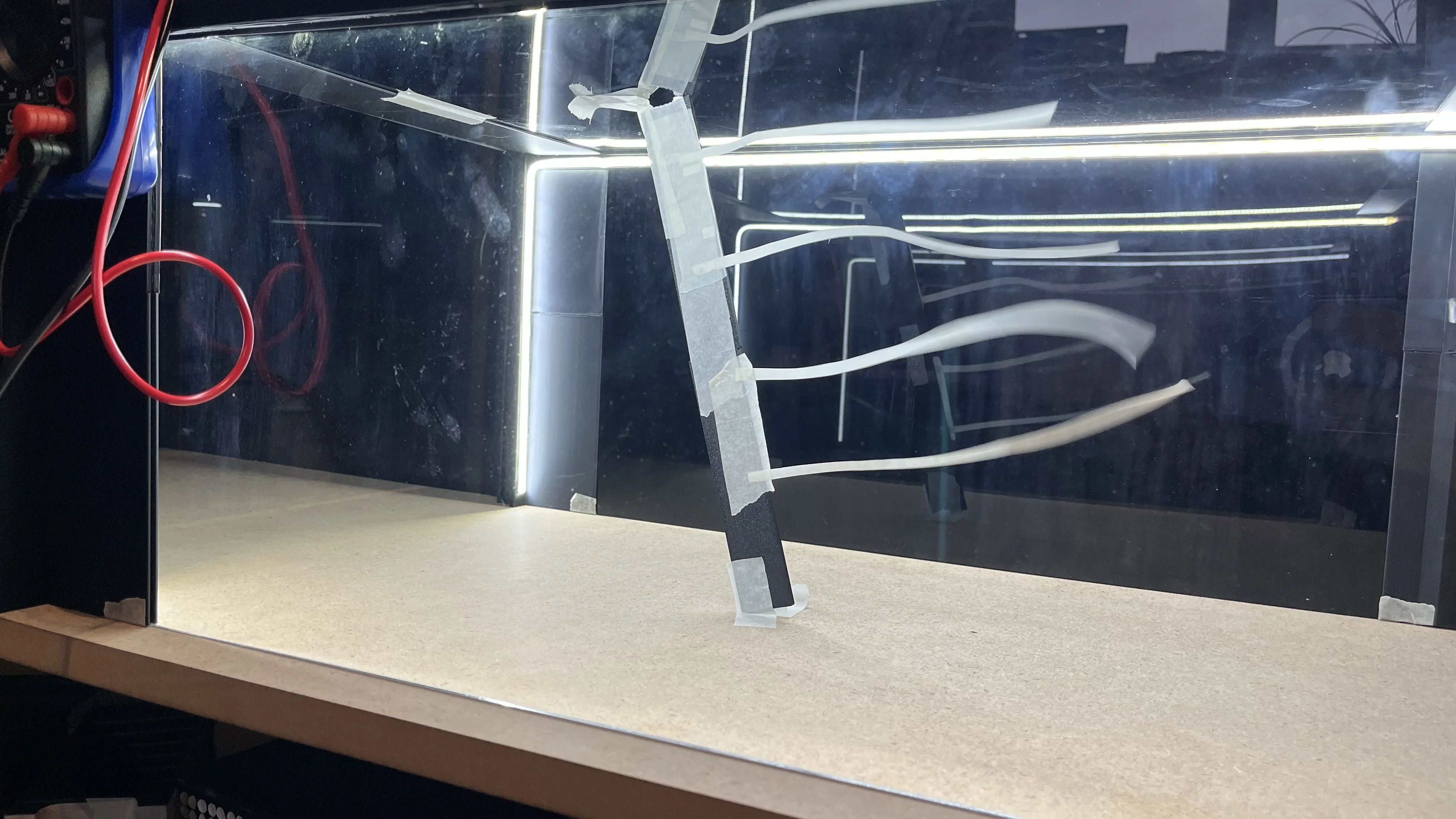

After conducting all of the previous tests and noticing a pattern of imperfect and quite turbulent flow, I began to consider a redesign of the flow system, including moving the fans to the rear of the test section to change the tunnel to a pull configuration. This design would reduce any turbulence from the rear of the fan and would provide cleaner flow in the test section. To validate this, I wanted a tool I could quickly place into the tunnel and test. I designed the structure pictured. The design is made to be as thin as could be reliably printed on my BambuLab A1 Mini, and also to reduce the wake from the frame. The tufts have also been made shorter after I realised that the previous tufts were too long and were moving around due to their delay in reacting to air movement. With shorter tufts, the visual flow was much more believeable and will allow me to compare designs as I begin to prototype them.

After running the test for a short period, I noticed that the structure was shaking near the top. To fix this, I will fix the structure to the base and top of the tunnel, likely with tape to reduce any vibrations. Also, although the structure is thinner, there will still be a wake around the frame. To reduce this, I plan to suspend thin wire/string between each of the spans and hang the tufts from there. This will reduce the wake as the string/wire will be much thinner and as a result have less imapct o nthe test results.

12th October 2025

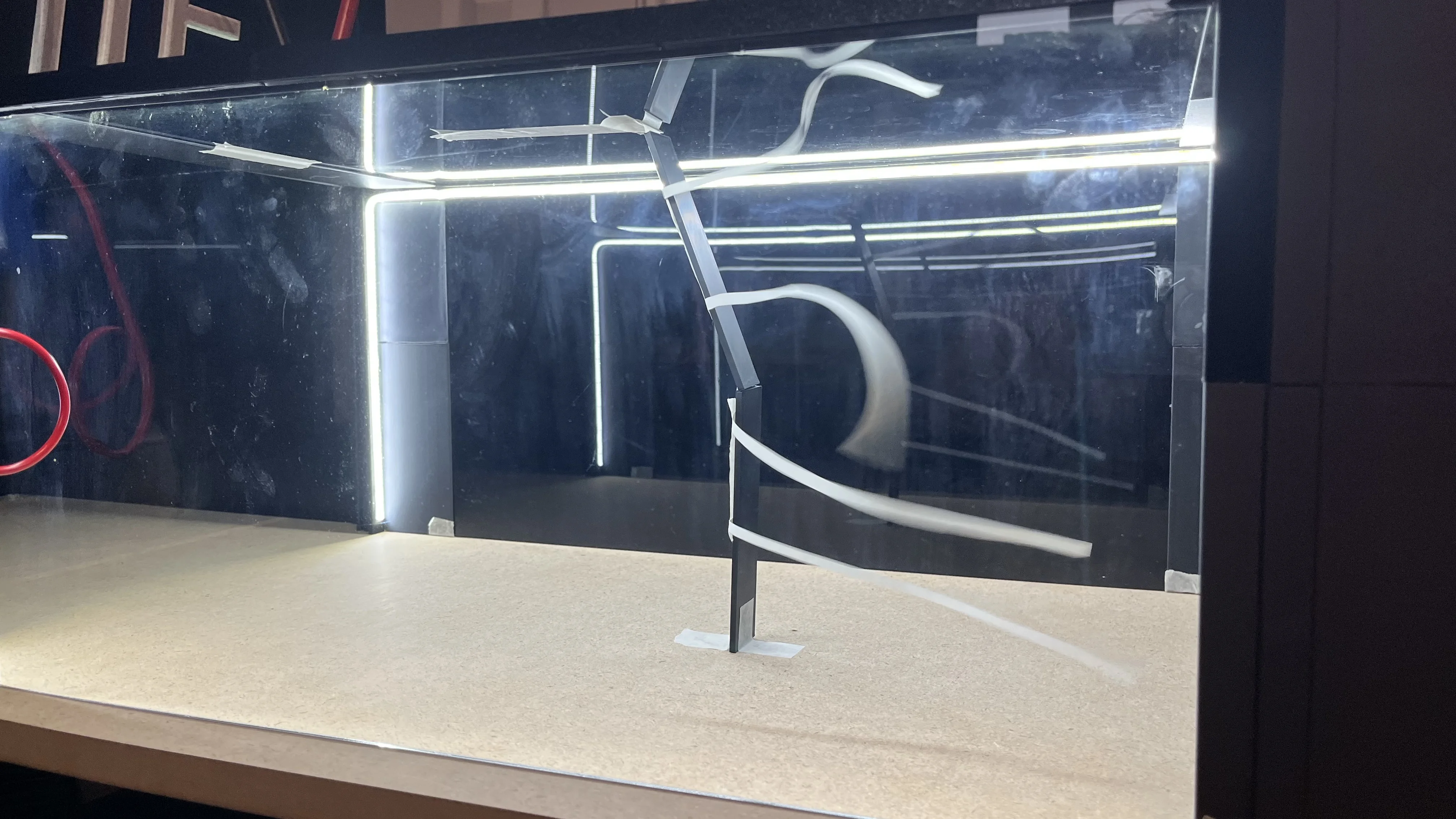

Running the previous tests with a stronger testing structure reduced the impact of vibrations on the tufts. However, the structure also caused a large wake and as a result, turbulence behind it, so to reduce this, I rotate the structure to its thinner side.

12th October 2025

To fix the issue of the weak tuft testing structure, I added other waste 3D printed parts to increase the rigidity of the structure and added more tufts to see flow quality across the entire height of the test section.

All tests were conducted at 14V (2V over usual fan voltage only for short bursts).

12th October 2025

After feeling the airflow of the fans before installing the airflow straightner, I wasn't entirely happy with the choppy air I felt. As a result of this, I began to look at how to redesign certain parts of the wind tunnel to imporve the flow quality of the design, without redesigning the entire project, which would have led to a waste of time and materials. To prove any new designs may work, I began to develop a testing system to prove the quality of the air has changed (if it does.)

An issue I noticed was that the structure I had mounted the tufts (made of paper) to was not rigid enough and caused some movement during testing, which affected reliability of the results.

11th October 2025

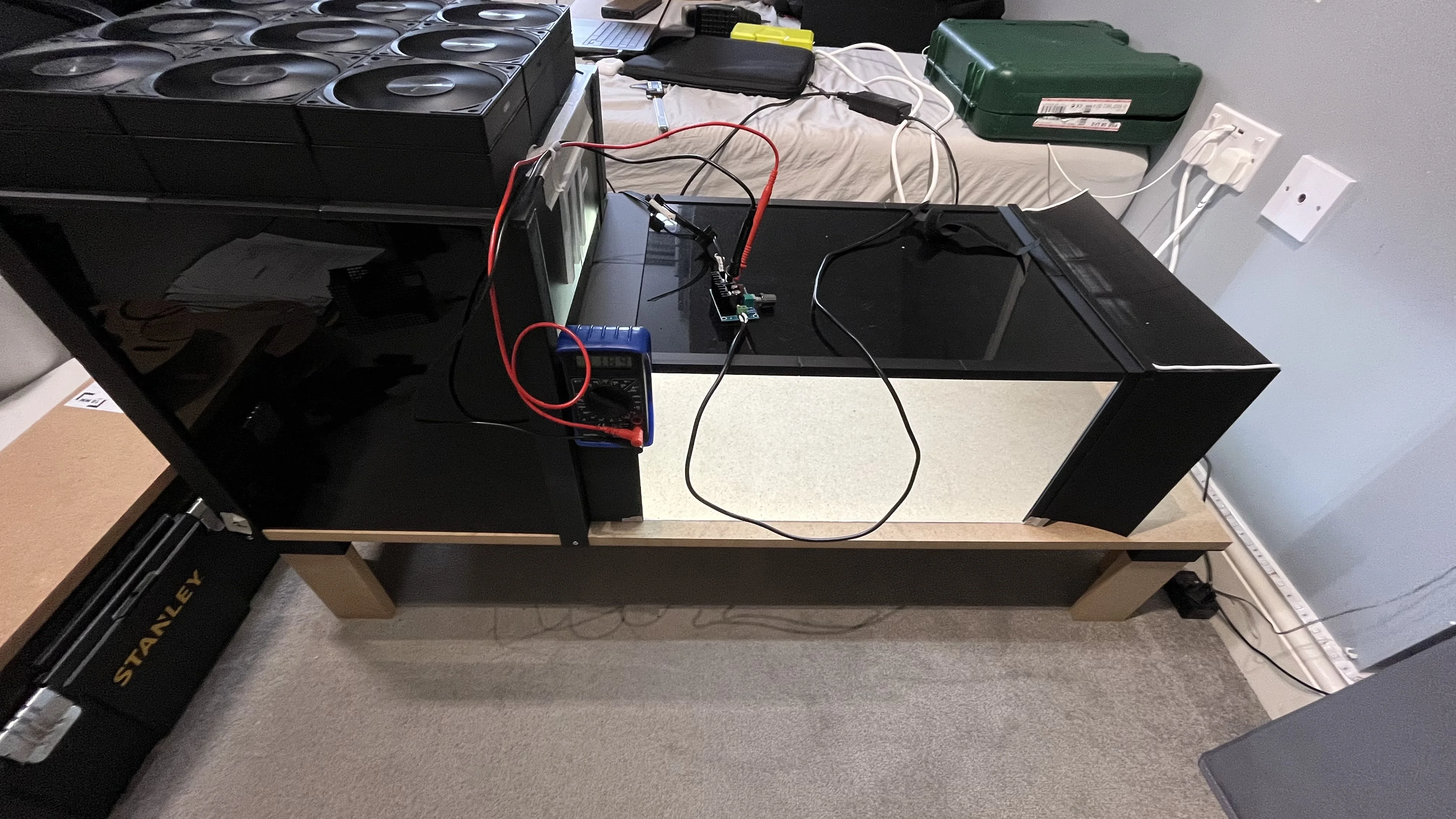

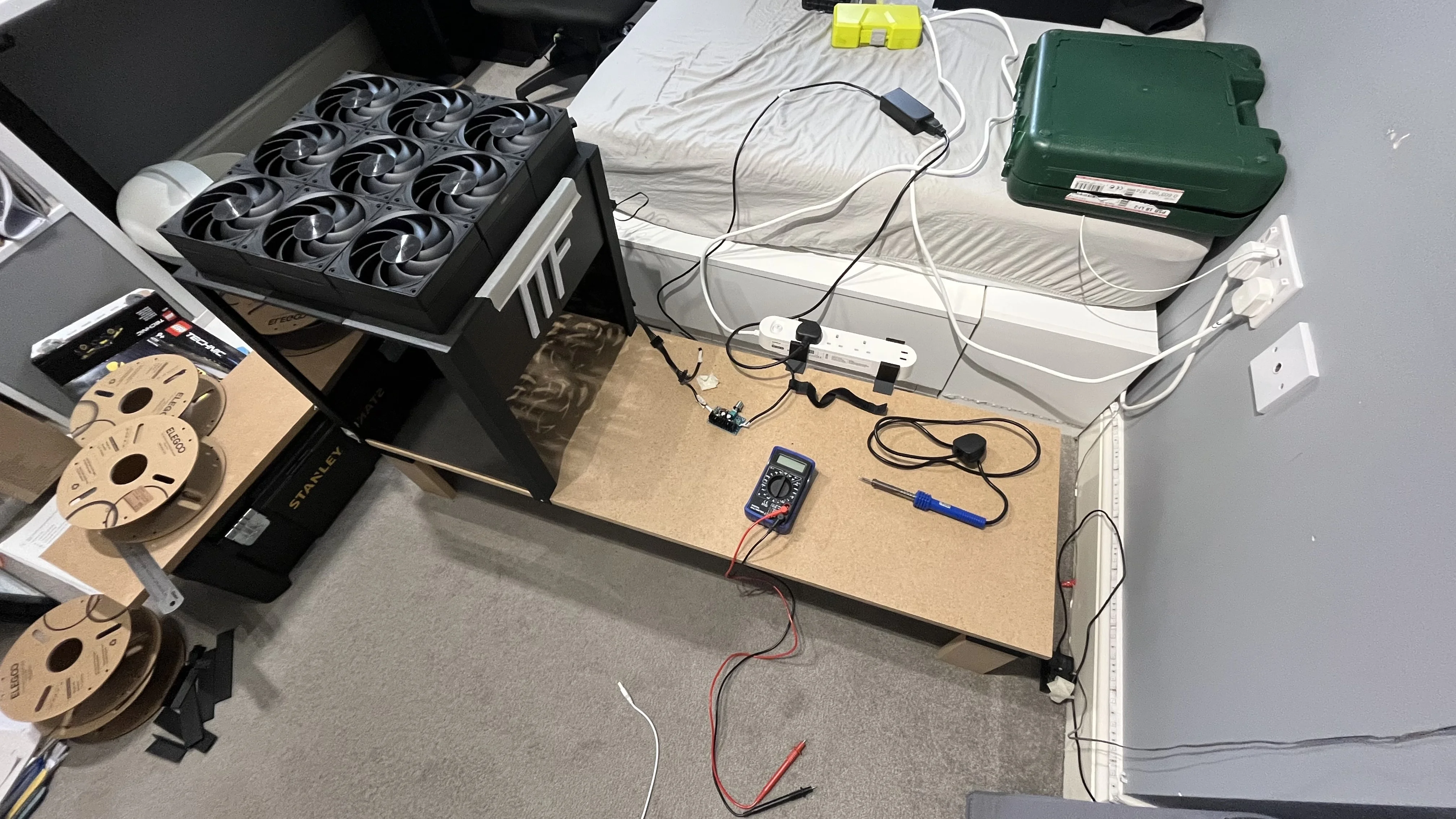

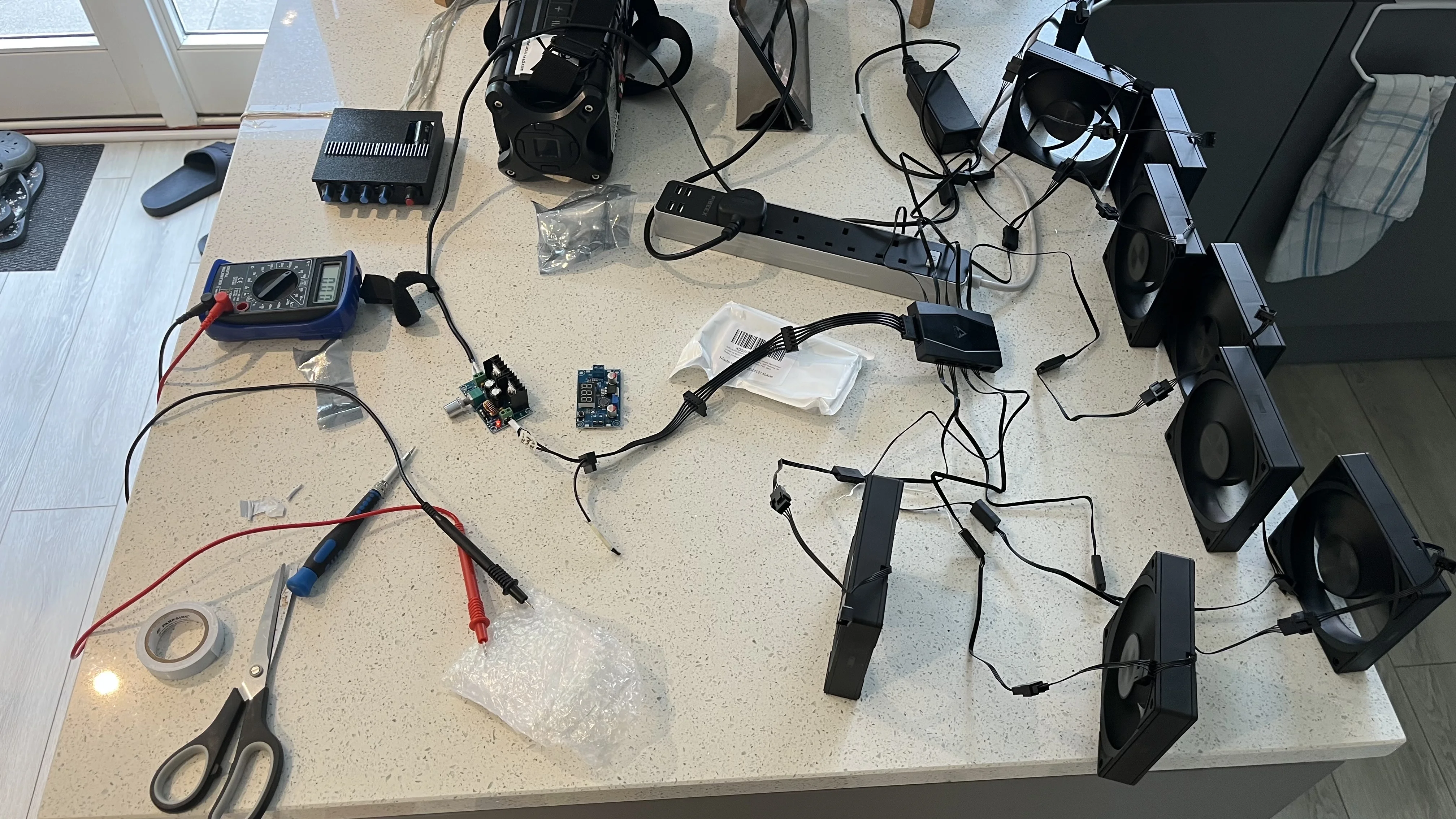

With the fans now mounted to the plenum, the array was ready to be tested to see if they could effectively move air once in their dedicated position, and also check that the lighting in the test section was effective.

11th October 2025

After purchasing 18mm MDF and cut to size, the base of the project is ready to be built upon. To start, the plenum frame was attached, then the acrylic panels could be inserted, and the fan assembly fixed on.

16th July 2025

I was fortunate enough to be able to spend half of a day with some of the engineers at Lotus to share and discuss the wind tunnel project. From this experience I learnt about how wind tunnels are used in industry and how my design can (and will be) improved. If any of the team I spoke to read this, thank you for all of your help!

12th July 2025

The fan bracket assembly is now complete, with labels for fans for easy identification and replacement as well as airtight side walls to ensure all airflow and pressure is directed into the plenum box.

12th July 2025

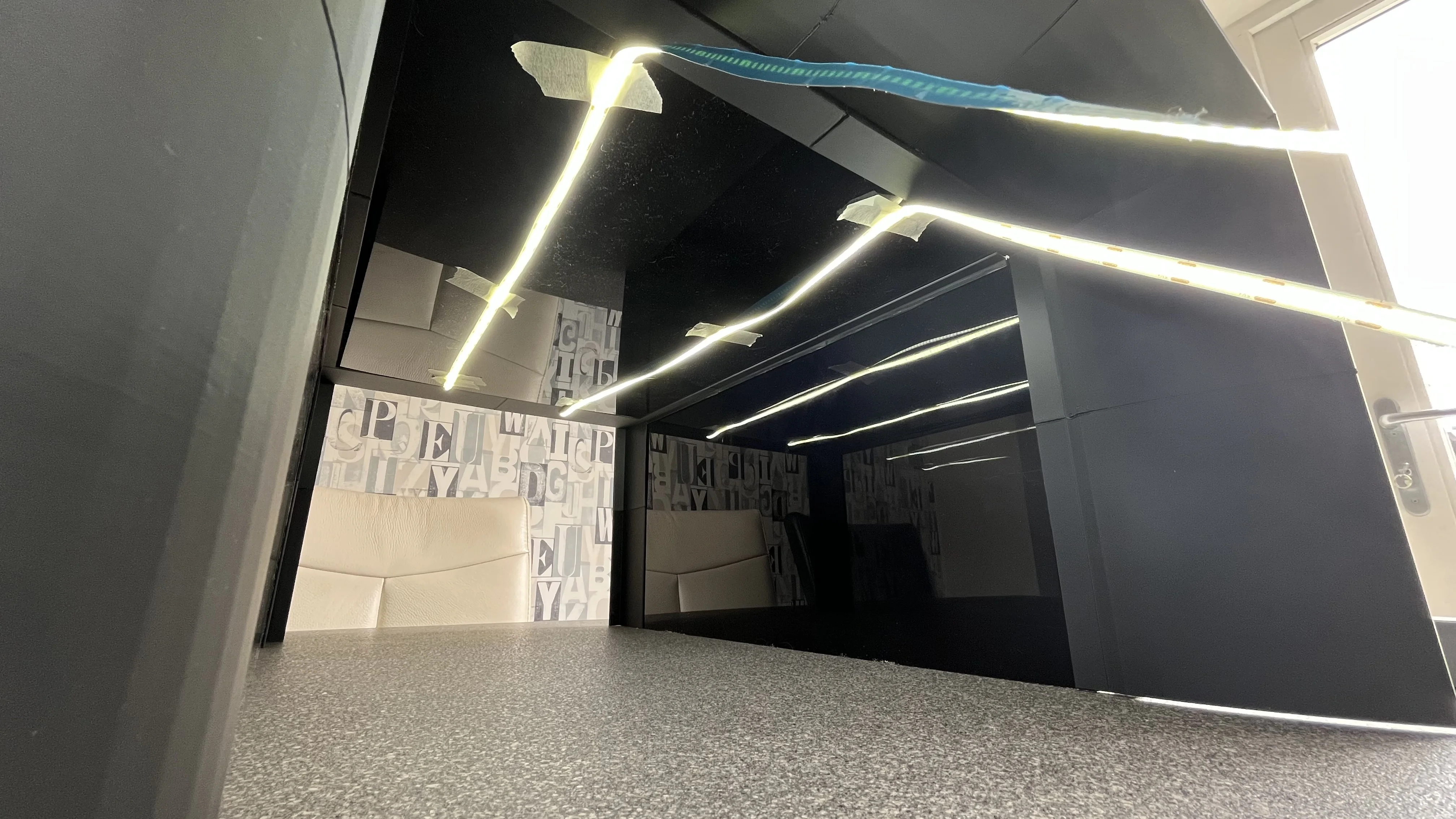

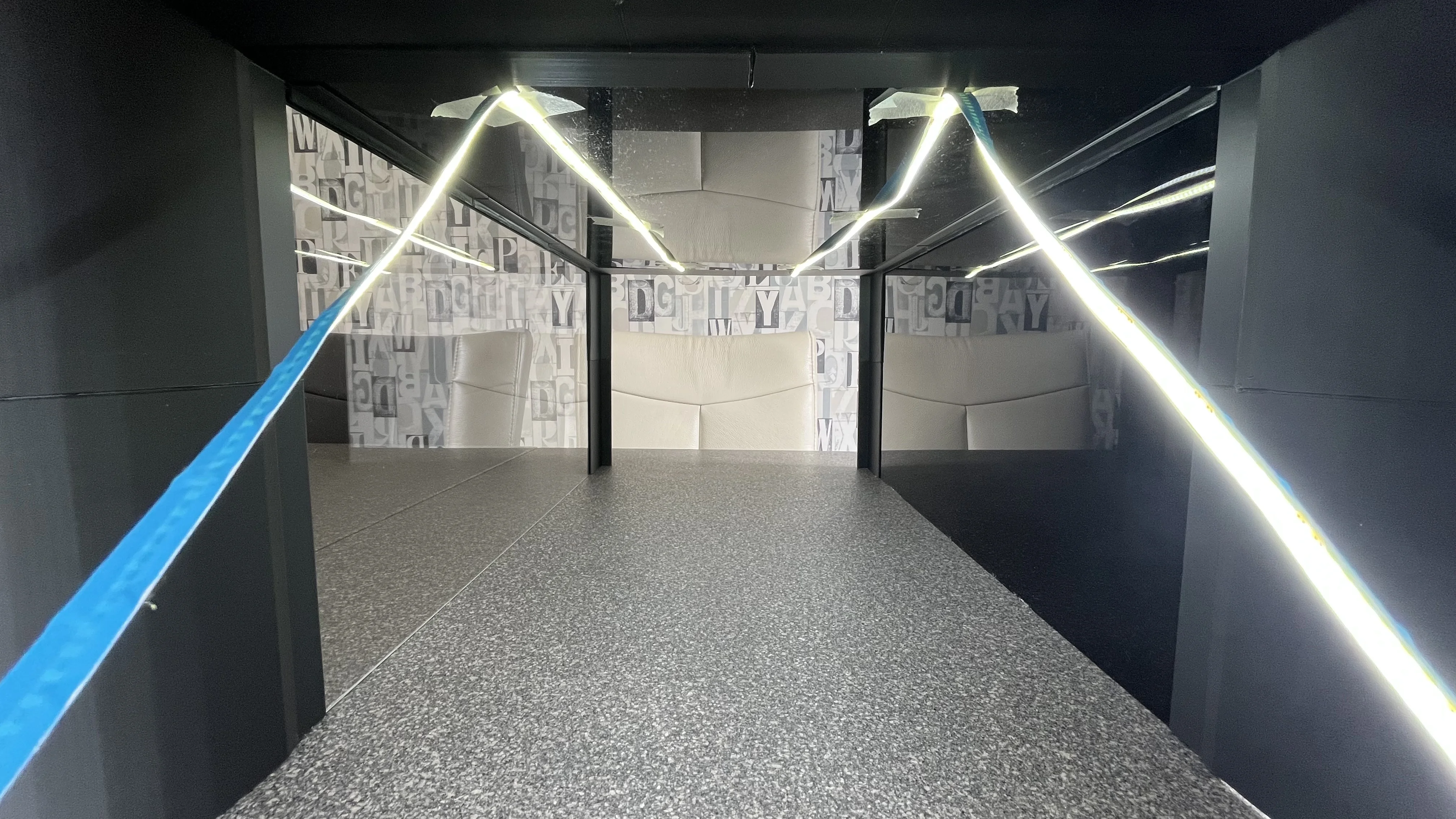

With the test section assembled, I can now focus on the lighting. The goal is to evenly illuminate the test section while minimizing shadows and reflections. The first, method I tried was to illuminate with two parallel strips. I settled for the LED strips attached to the top corners pointing 45 degrees into the centre.

12th July 2025

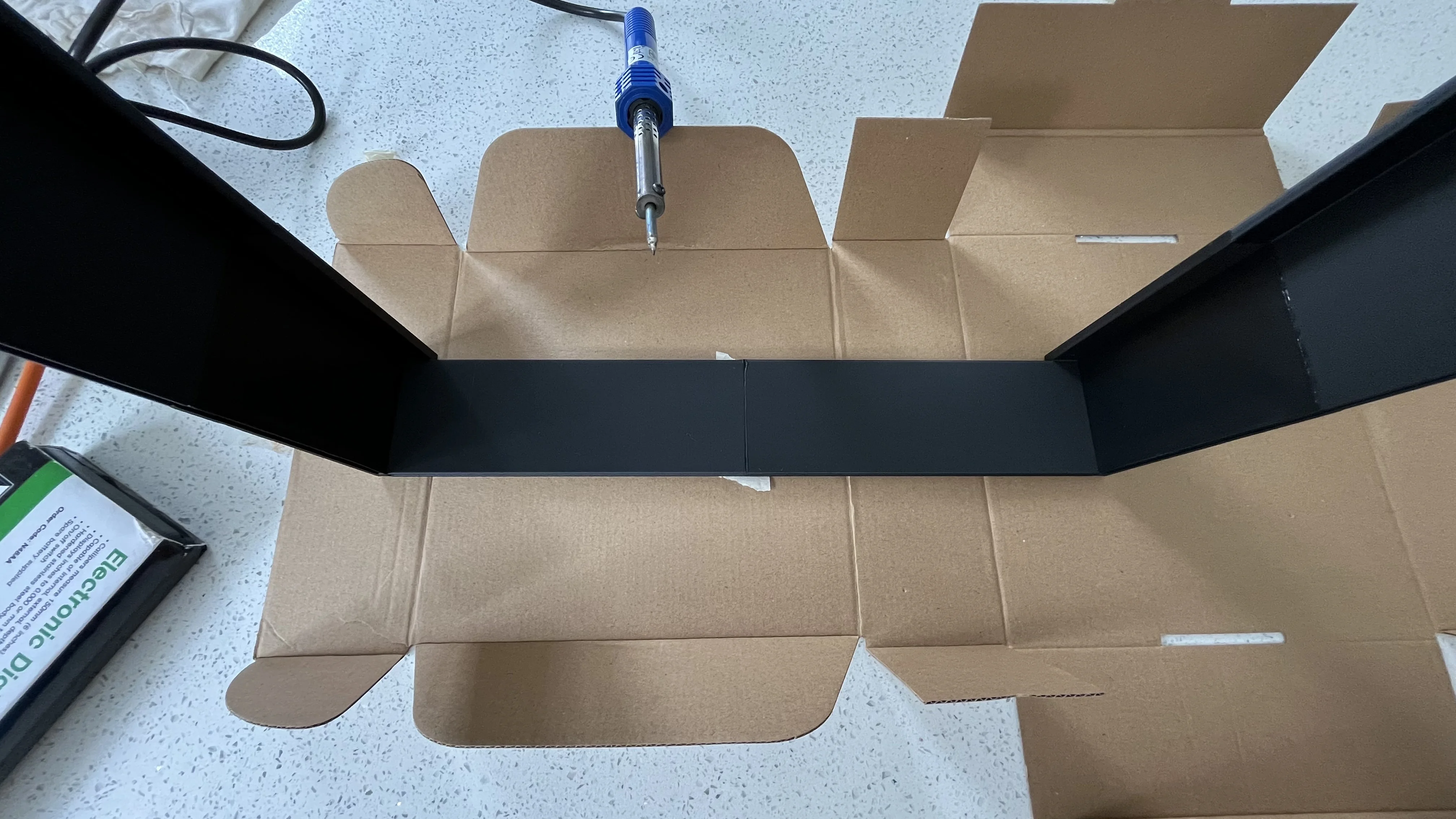

With the test section having its major components 3D printed or sourced, assembly can begin. The design has been optimized for ease of assembly using the plastic welding technique and took a short amount of time to put together.

An issue that I noticed was how reflective the back panel of the test section is, which may cause a lack of contrast in any visuals. To solve this, I will test an offcut of acrylic with different surface finishes to determine the best solution to this problem.

12th July

To avoid using super glue, creating a mess and potentially ruining the appearance of parts, I used plastic welding by using a soldering iron to melt the joints between parts. This technique allowed for strong joints with almost unnoticeable seams.

9th July

To get a rough idea of what the final design will look like, I assembled the completed pieces, using the acrylic (with wrap still applied). The design will accommodate large models and allow for great visual testing.

9th July 2025

The fan bracket has been designed, 3D printed and mounted. Initial tests show that it is able to hold the fan securely in place while also allowing for easy removal and replacement. The LED's have also been tested and are very bright and consistant - perfect for illuminating the test section.

6th July 2025

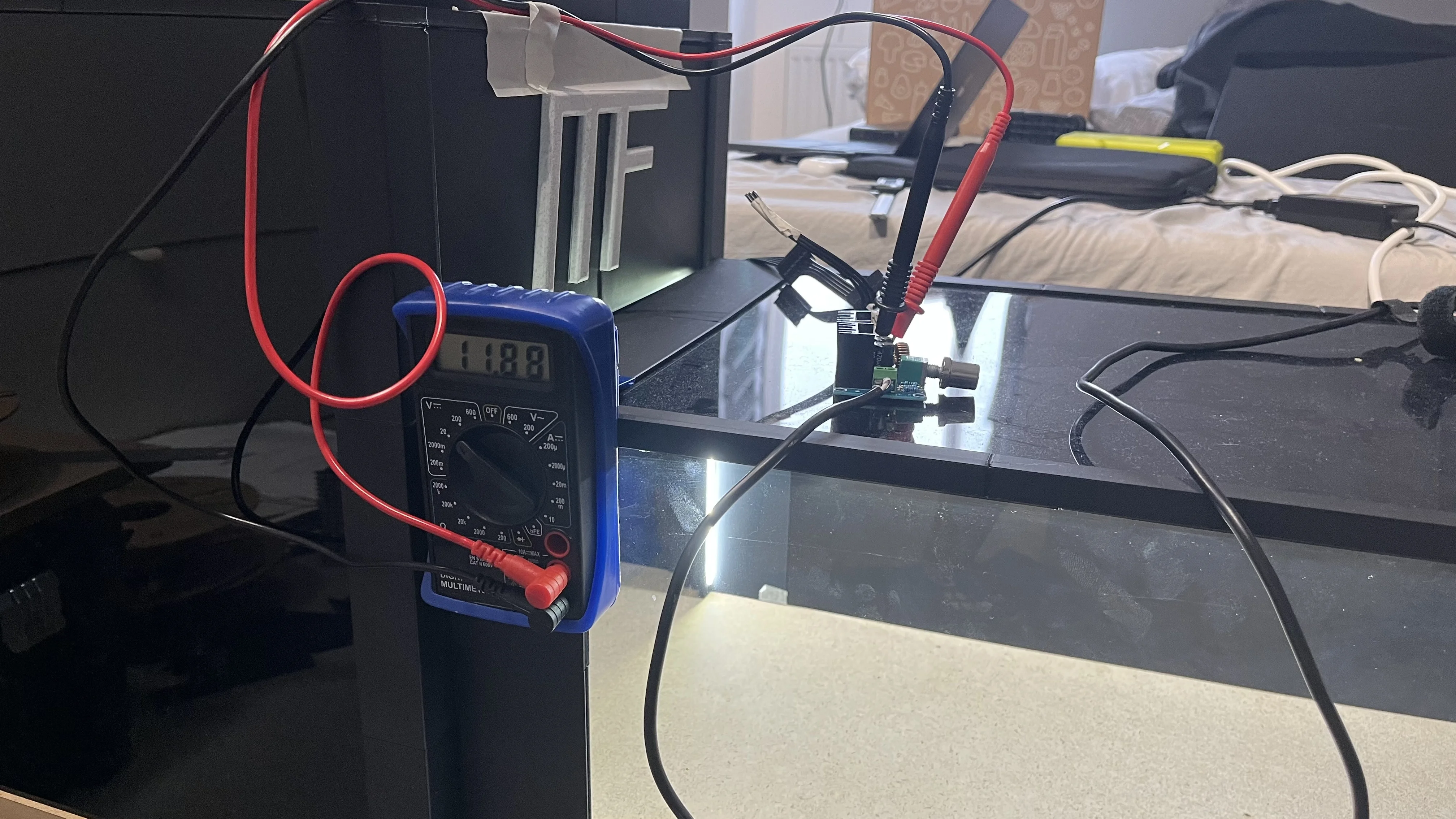

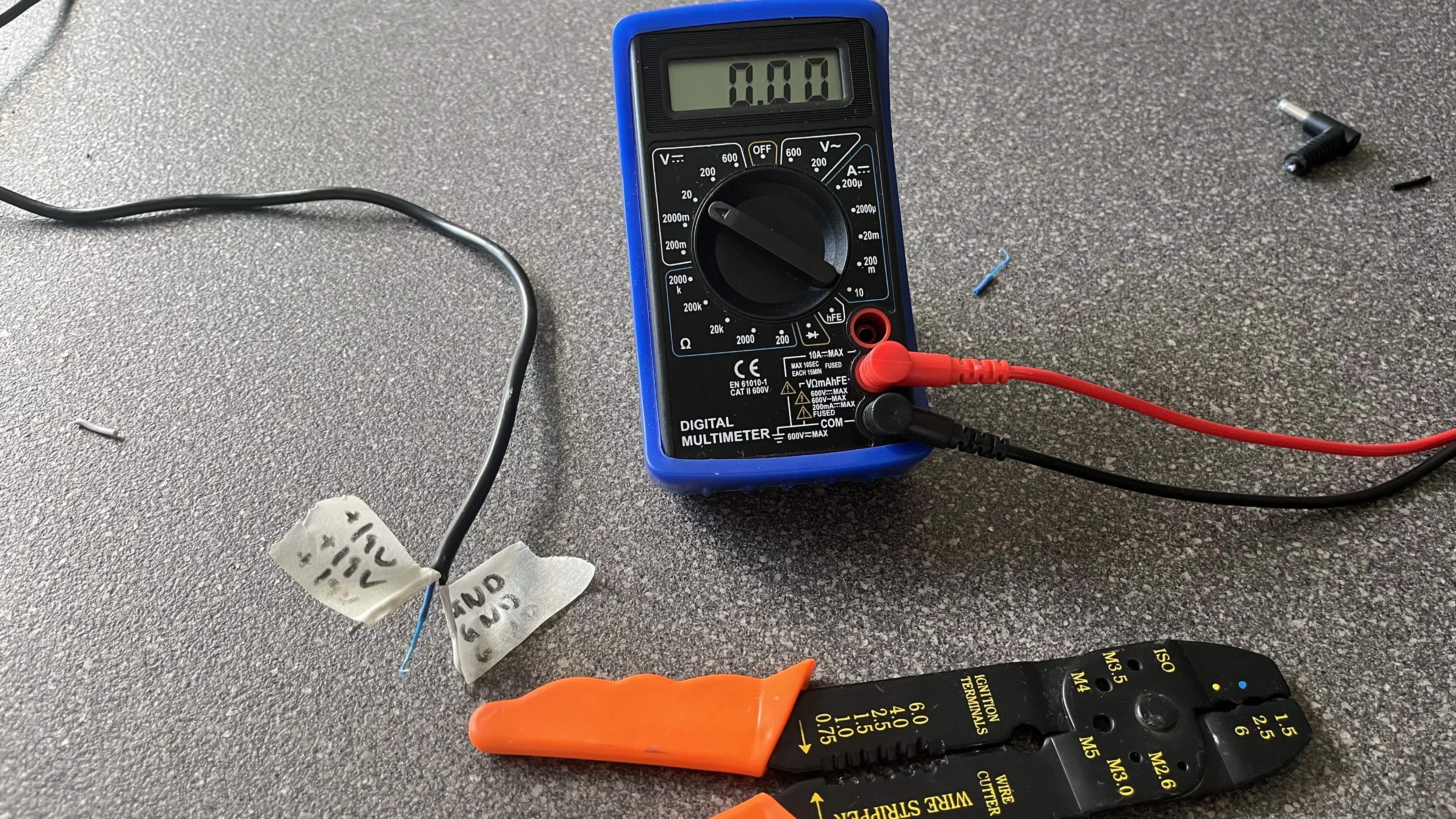

Due to issues with the original buck converter (coil whine and high temperatures), I have replaced it with a new model that has better thermal performance and higher current capacity. The new buck converter is showing no issues and all 9 fans run perfectly.

30th June 2025

With sponsorship of the acrylic for the test section and plenum, I am now able to being working on the parts the acrylic will connect to. The first one I started with was the airflow diffuser, mainly due to 3D printing filament constraints.

27th June 2025

To save on cost for powering the fans, I will be using an old laptop power supply and SATA power cable. To ensure this will be safe and set up correctly, I used an online SATA pinout diagram to work out which terminals are which. This then allowed me to decide on a DC-DC buck converter to take the 19V from the laptop PSU and convert it to the 12V the SATA cable is expecting.

(I am using SATA as the fan hub the design uses is powered by SATA)

12th June 2025

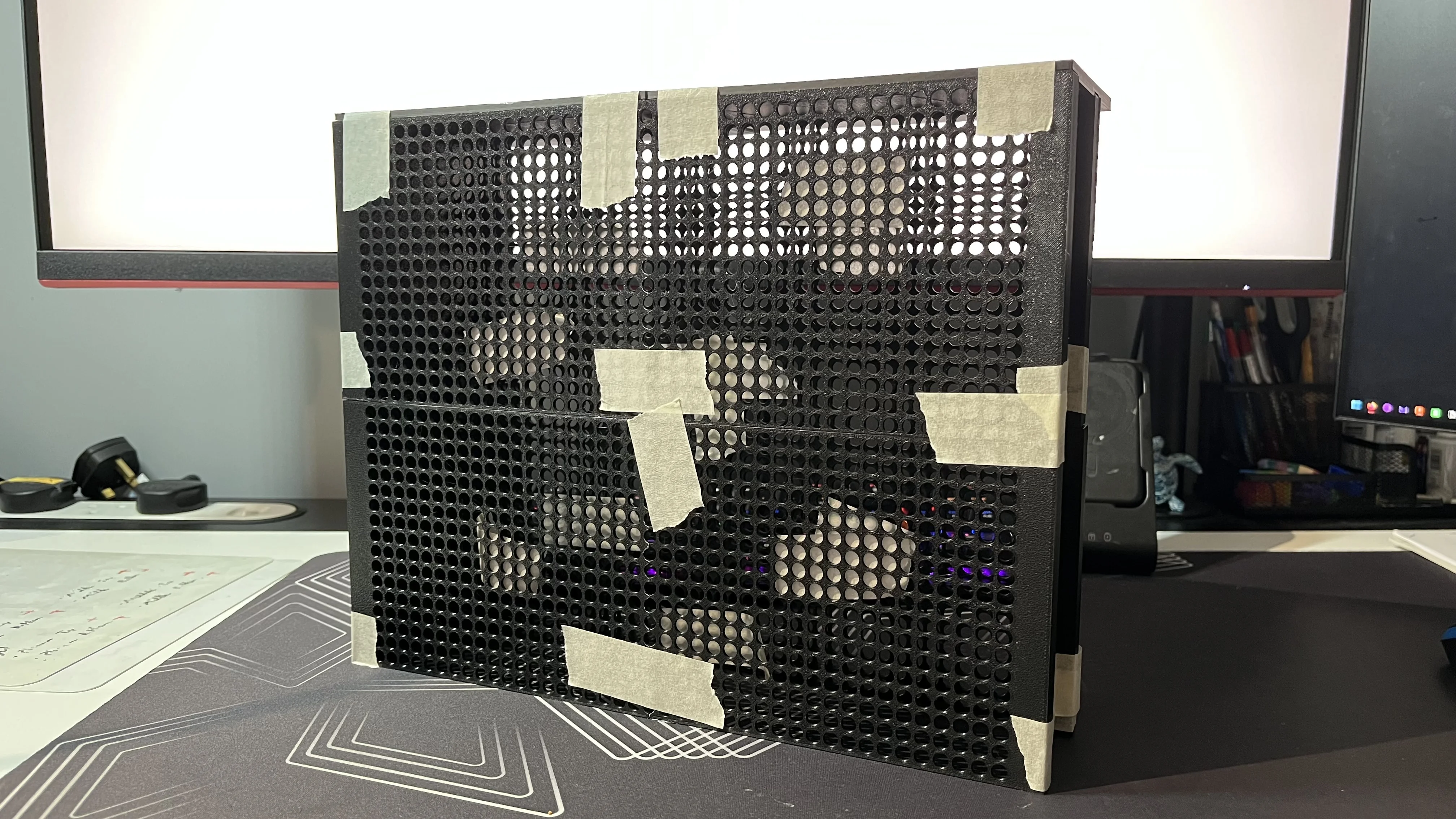

With the CAD complete, I could now being the manufacturing of the parts needed in the build. To start, I 3D printed the most complex part: the airflow straightener.

To test the fit, I used masking tape to hold all the parts together and found it fit excellently.

9th June 2025

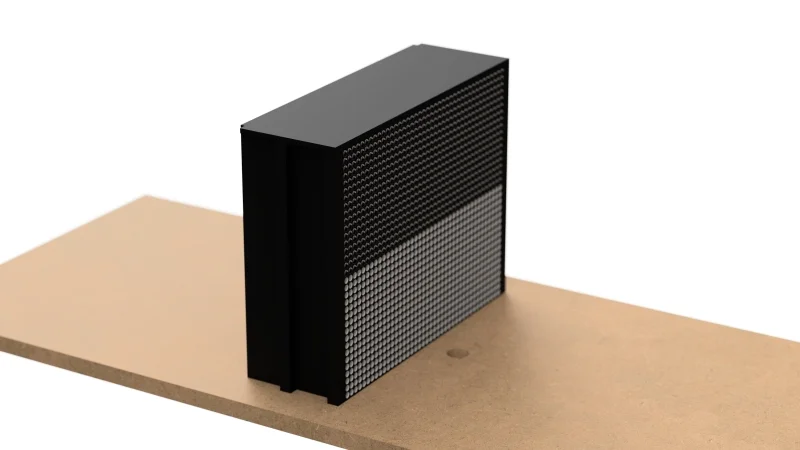

After researching wind tunnel design, HVAC concepts such as plenums and setting the project goals, I designed the first version of the wind tunnel using Fusion 360. The design is split into 4 main parts:

To read about the entire project, click the link below:

Wind Tunnel V1 →